Vision Experts from Karlsruhe, Germany and Mabeg Systems from Mörfelden-Walldorf near Darmstadt, Germany have decided to collaborate in the field of automatic carton sorting.

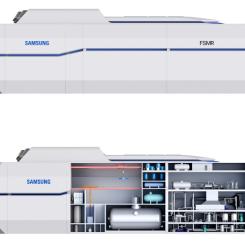

The initial outcome of the cooperation was the integration of the Vision Expert 4000 Carton print inspection system into the Modular Blank Inspector by Mabeg Systems. The solution that emerged has been designed for manufacturers of cartons and cigarette packets, who want to ensure 100% reliable and reproducible optical quality control of their products. The solution works by placing the products in a pile in the sorter, automatically isolating them and passing them under a camera with high throughput. The connected Vision system recognises printing errors and marks and steers the defective product onto a different track. Thus faulty products are automatically extracted. Depending on their size, up to 40,000 products per hour can be checked for colour deviations and text errors, ink splash and other printing errors, as well as punching errors and soiling. There is also an option for the inspection system to support a PDF comparison, which is an important function for the quality control of pharmaceutical packaging. It is very easy to operate and get to know the equipment. Punching outlines and any restricted testing areas can be taken care of directly from the preliminary stage, making operation even easier. The scope of delivery also includes comprehensive recording of all errors found in a batch, both in a database and as a printable document.